Graphics in motion

GRAPHICS IN MOTION

Audiovisual Design

Some free time fun with after effects and cinema 4D

Lost into trying | Son Lux

Designit Logo

Balance Bike

Bubbles

Smooth Criminal | V David Garrot

Soft | Music : Lackbear Califormula

Circle Bomb

"Same" Boxes

"SAME" BOXES

Photography

Photo series of post boxes each in their natural habitat and their own personality.

Left alone objects

LEFT ALONE OBJECTS

Photography

Series of photographs taken thoughout the years, capturing the objects randomly placed and left in public places. I found it tragicly funny, emphatising with the objects and thinking about all the efforts put into making.

Adana – Turkey, October 2018

Rätvikk – Swenden, July 2017

Simrishavmn – Sweden, July 2017

France, March 2019

Dragor Denmark, June 2017

Copenhagen Denmark, May 2017

Demirci – Turkey, August 2018

Copenhagen Denmark, February 2017

Muwi

MUWI

Compact & Versatile Motion Control for Smartphones & Cameras

A product family that grows as you go

This has been an exciting project that I worked on with two former colleagues/friends. We took the concept from scratch to the final product and now, we are on Kickstarter! 🙂 Exciting times ahead of us. Stay tuned…

2018 | Partners: Anıl Ercan & Sözüm Doğan

With the links below, you can find out more about Muwi.

Avo

AVO

Interactive ping-pong console

An audio-reactive gaming system that makes ping pong more playful

The overall aim of this project was to explore how sound and light can be used in the product and interface design as well as to explore the relationships between sound, imagery and form. As a team of 4 students, we have been focusing on enhancing the experience of playing ping-pong.

2016 | 2 weeks | Teamwork with Eduardo Ferreira, Yi-Ting Chien and Yuanrui Li

Concept

Process

Miko

MIKO

Welding companion for small scale-metal workshops

How might we introduce collaborative robots into small scale workshops to increase safety among workers?

Vision for collaborative robotics | Small-scale or large-scale?

The way collaborative robotics are seen today is solely humans and robots working next to each other without the robots harming the human. However, working collaboratively is more about communication, support and helping each other. This does not happen in large-scale production facilities because the tasks are monotonous, and the robots do not need to be reprogrammed that often. With this set up, robots stay as machines working behind cages. Bringing industrial robotics from large-scale to small-scale production facilities opens a room for true collaboration between humans and robots with a high level of interaction. In the small scale workshop, the robot can become a co-worker rather than a machine working next to you.

Miko is a professional welding robot for small-scale metal workshops. It is designed to work in a close collaboration with the welder. Small-scale metal workshops compete with larger production facilities by being able to offer flexibility. This requires them to have an agile process and equipment that is efficient and easy to set up. Miko aims to bring automation into the small-scale metal workshops. With the help of the teaching tool Link, Miko is fast to set up and does not require any prior skills in programming. With Miko in your team, you can avoid health risks caused by exposure to harmful fumes, strenuous positions and UV-light. Miko finishes the job while the welder is planning for the next one, increasing efficiency and safety in small-scale metal workshops.

2017 | 8 weeks | Teamwork with Jakob Dawod & Jon Sommarström

in collaboration with ABB Corporate Research

with user feedback from Allmek Svets

IDEA 2016 Silver

“Both me and my colleague Micke had to go through shoulder surgery because of the unusual work positions like positioning the arms above the head”

Mobile to adapt momentary needs

Traditional industrial weld robots are one-off solutions where perform one task repeatedly in a fixed position. It became obvious during our field research that in small-scale workshops there is a need for flexible automation. Welder’s tasks vary from day to day and that their workstations are transformed according to the needs of the job. Because of this, the solution had to be flexible to be able to help wherever needed; and provide a wide reach to cover variety of different tasks.

Easy set-up

Small-scale workshops having 5-20 employees, cannot afford hiring specialist to program welding robots. This hinted that the product had to be easy to operate so that any welder could use it without prior knowledge of programming. Link is the main interaction tool between the welder and the robot. The welder shows the weld path to Miko by simply going over the edges with Link. With the help of indoor triangulation system and image recognition, Miko knows where to apply the weld. Link makes it possible to operate Miko in a more natural way, similar to how welding is done today. Because of this, Link’s semantics are inspired by the traditional weld guns.

Activation & Feeling in control

Miko is activated by docking Link into the interface. This way, we aimed to give a feeling of control to the welder.

Light Guard

When welding you need to take into considerations your colleges around you. Being exposed to the light from the arc can cause eye damage. The adaptive Light Guard makes MIKO into a safe assistant in the workshop reducing the risk of coworkers being flashed by the arc from the weld gun. It extends or retracts depending on ease of access to the weld area.

Approachable

Today cage free industrial robots are safe to be around. They work at low speeds and stop when a person gets too close. However, delivering the feeling of safety and being safe is two different concepts. For a collaborative robot working next to humans, it becomes important to deliver a feeling of safety. Based on these insights, we worked on the semantics of Miko and tried to balance friendly character and performance driven workshop product look. To give predictability to its actions, Miko shows its direction of movements with projected lights on the ground.

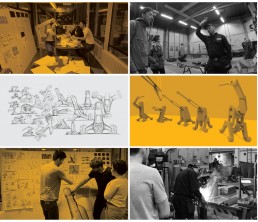

PROCESS

5 days Sprint

I got familiar with using sprint for product design projects during my time at Designit. Since this project was quite short, we decided to kick off with a sprint week to get it going quickly. At the end of 5 days, we created a low-fidelity scenario movie and archetype options to see users immediate reactions and make a decision accordingly. With the 1:1 scale low fidelity model, we were able to test reach with respect to sizes of workpieces in small-scale metal workshops.

Process Video

Archetypes

Workflow

Highlights

Harken Screwdriver

Harken Screw Driver

Brand & Product Analysis

Take an existing screwdriver, add a new functionality, rebrand it and make it work with the existing components

The focus of this project was to design for manufacturability and visual brand expression. Provided with internal components of an existing screwdriver, we were asked for designing a screwdriver with an added functionality for a brand of our own choice using the same components. The challenge was to use 17 hours in total for the visual analysis and documentation of the brand, the ideation and design of the new screwdriver; and having a functional prototype at the end of 4 weeks.

The final result is a screw-driver designed for Harken, an international manufacturer specializing in performance sailing hardware and industrial solutions, with a bits storage function-X.

2016 | 4 weeks | Individual work

I was trying to make enclosure clean and seamless from both sides. In the final proposal, screws are placed in the inner shell.

Touch the Light

TOUCH THE LIGHT

Physical Interaction Exploration

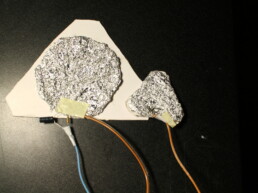

It was a self-initiated project which I start with the motivation of learning more about physical computing, seeing how it would be to create both software and hardware which works together, and exploring what interaction with a machine/device could be beyond pushing buttons, touching screens, or waving to proximity sensors. My initial ambition was to create a responsive fabric material woven out of conductive rubber cord, a flexible material changes resistance when stretched. So everything would be more honest, and we would be interacting with the material itself. But that didn’t happen because I couldn’t get the material to work stable enough. So it ended up being waving to a proximity sensor again, but it was fun trying:D

Evrim Şahin, my beloved physical computing instructor from bachelors, was mentoring and helping me figure out things along the way.

2015 | Self Initiated | 8 weeks on free time

Designboom LED Life, Finalist

Each surface corresponding to one of the red, green and blue channels

Mixing up and creating different hues for the light

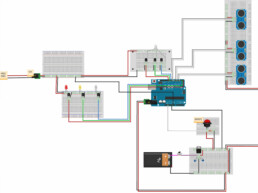

It was a lot of trial and error in the process. Especially with the conductive rubber cord that I was planning to create a woven fabric surface. Although it didn’t work out for this project, it is a cool material check it out here if you are interested. I was also looking for a easy to use/ beginners tool to plan the circuit. Frizting is pretty nice for that.

Transistors | IRFZ44N Metal Oxide Semiconductor Field Effect

Transistors | BD 135 NPN Bipolar Junction transistors x 3

Heatsinks for transistors

Power Supply 100W Single Output Switching Power Supply

FLB6 RGB Color Series Strip LED

Single color LED’s, red-green-blue

22K resistors & 1 μF Capacitors

Conductive rubber trials

Starting small with the circuit

Some planning with Fritzing

Freshly homemade switch

Duo

DUO

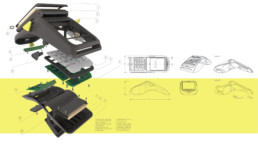

Portable EFT POS device offering multi-sensory feedback with improved security and privacy

How might we qualify vendors and payers as different user groups to meet their varying needs, and give a sense of privacy and reassurance to payers?

The mobile payment devices become more and more complex, incorporating the functionality of cash registry and payment devices into one. The approach of having only screen-based interactions makes it possible for the vendors to operate cash registry features and access more information. However, the more digital it gets, the more touch and feel we lose. DUO aims to meet varying needs of vendors and payers by focusing on digital interactions at one side, and tactility on the other. It provides multi-sensory feedback to meet with needs of the minority and draws a clear line between vendors and payers actions to improve the feeling of security.

2014 | Individual Work | 12 weeks

in collaboration with Futero Design

with user feedback from Association of Visually Impaired

IF Design Talent 2015, Reddot 2015 best of the best

‘‘Considering that mobile payments can be more and more prevalent than ever, this design implies a caring consideration to the minor people’s need, meanwhile, the rotatable display indicates a smart UX feature through the connection of software and hardware factors.’’

iF 2015 Jury-Statement

Payers Side

Vendor’s Side

Process Highlights